【产品动态】Model 9120啤酒在线分析仪-New

In modern beer brewing, much of the original craftsmanship is being taken over by fully automated installations. Where product quality was often maintained by skilled personnel and where the brewing process, in many cases, was controlled by visual checks and experience, modern breweries ask for automated and repeatable instrumentation to keep track of product flows, both quantitatively and qualitatively.

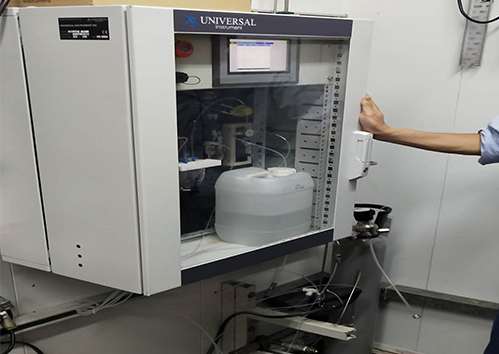

Rhosonics Analytical devellopes and produces ultramodern insitu, drift-free analysers for optimized process controll. The program consists of an overcomplete set of mostly non-intrusion insitu ultrasonic analysers, consisting of State-of-the-Art sensors, hard- and software techniques that no other supplier has shown before. For example:

the determination of alcohol without using the ever fouling U-tube sensor

the use of special software to prevent interference with gas bubbles, signal weakening, external influences and others;

the use of UltraSmart software resulting in an increased total accuracy of the measurement!

the option to use Profibus DP, Modbus and TCP/IP communication protocals and to connect to ethernet

the integration of very high resultution conductivity, pH, DO and low range turbidity probes;

full graphical colour touch screen interface, easy to operate with.

In beer brewing the following applications are fully under control by analysers:

Mash and Lauter tun, for inline control of Wort Plato index, extract concentration and density

Wort kettle, for inline control of Plato index and extract, O.G., density, alcohol

Cold Wort, for inline control of Plato index and extract, O.G., density, alcohol

Blending, for inline control of Plato index and extract, O.G., density

Bottling, as Pipeline Interface Detector

In many utilities, for example COD in sewage measurement